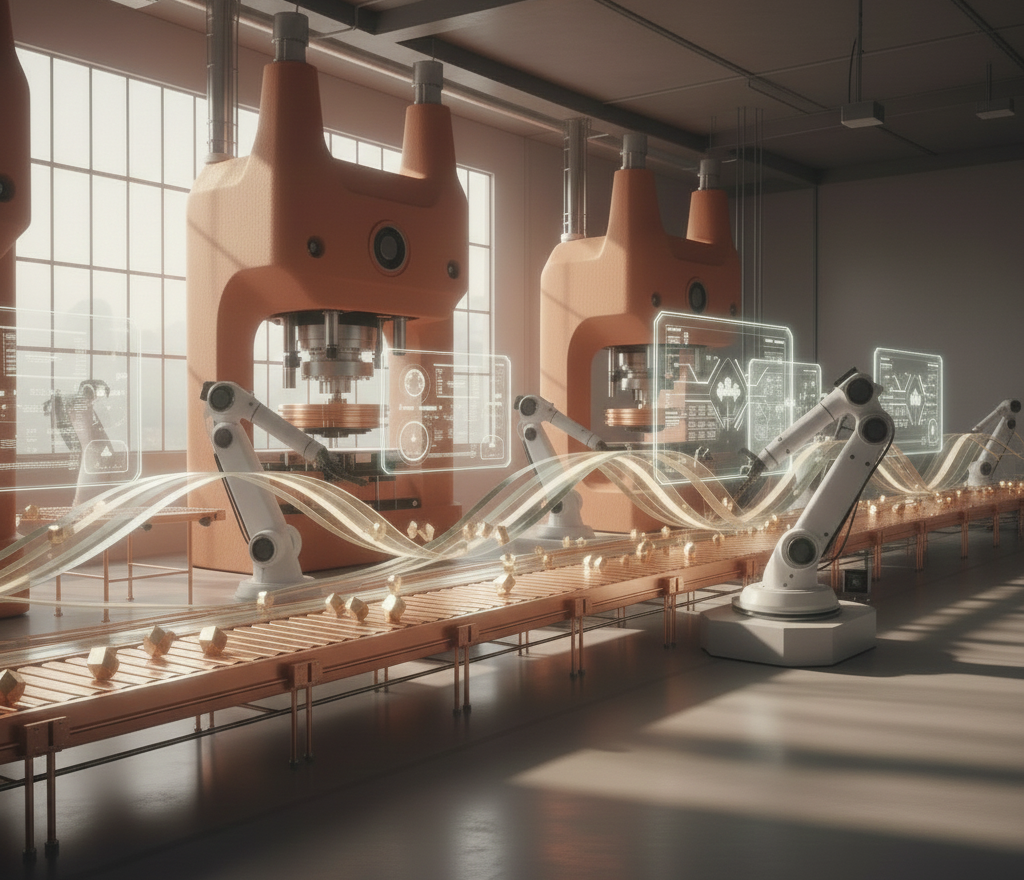

Walk into any modern factory today, and you’ll notice something interesting: the most productive teams aren’t made of humans or robots alone

They’re built on human–machine collaboration.

For many years, automation was thought to mean that humans would be replaced by machines. However, the manufacturing wave of 2025 has completely changed the story: the most intelligent factories are empowering workers with AI-driven collaborators, or “cobots,” that greatly improve workflow speed, safety, and efficiency.

And here’s the stat that usually surprises leaders:

Plants that deploy AI cobots report up to a 30–50% reduction in process time and 20–40% fewer operational errors within the first year.

The reason?

Cobots don’t replace judgment—they eliminate the friction that slows it down.

Picture this scenario:

A technician is assembling precision components for an automotive parts line. Previously, the work required constant measurement, alignment checks, manual tightening, and multiple QC stages. One mistake meant recalibration—and lost time.

Now imagine the same technician paired with an AI-enabled cobot.

- The cobot handles repetitive alignment.

- It adjusts torque in real time.

- It highlights micro-deviations before they occur.

- It alerts the technician to anomalies before a breakdown becomes a costly issue.

The human focuses on the critical decisions. The machine handles the precision. Together, they operate like a single intelligent unit.

This isn’t futuristic—it’s happening right now across electronics, automotive, aerospace, textiles, and FMCG plants. AI-powered cobots bring something traditional robots never could adapt to.

They collaborate dynamically with the person in front of them, learn from patterns, and adapt to changes rather than merely obeying orders. For this reason, cobots are becoming increasingly popular not only in large factories but also in small and mid-sized businesses.

Another subtle function of AI cobots that is often disregarded is that they lessen fatigue. Workers report lower cognitive load because the machine manages the complexity. And when fatigue goes down, quality goes up.

This has sustainability benefits too. When error rates drop, waste drops. When precision improves, power consumption reduces. When workflows sync, downtime decreases.

That’s why cobots are becoming central to low-emission, energy-efficient manufacturing strategies. Factories using AI-assisted automation have seen up to 15–25% reduction in energy usage—not because of new hardware, but because processes became smarter.

And that’s where Ratovate’s approach fits in.

Instead of selling automation for automation’s sake, the goal is to augment people—the most valuable asset in any plant. Ratovate’s AI systems don’t just execute; they sense, predict, adapt, and guide. They turn every workstation into an intelligent, collaborative environment.

This is the future: not replacing skilled workers, but giving them superpowers.

So the real question for manufacturers now isn’t “Should we automate?” It’s “Are we empowering our teams with the intelligence they need to outperform?”

If you’d like to see what an AI-assisted workflow looks like inside a real factory, message me. I’ll walk you through a visual example of a human–cobot workflow that cut errors by 42% and energy use by double digits—without replacing a single worker.